rockwell hardness test and ductility|rockwell hardness testing procedure : purchaser 4.1 The Rockwell hardness test is an empirical indentation hardness test. Rockwell hardness tests provide useful informa-tion about metallic materials. This information may correlate to .

15,734 novinha 18 anos FREE videos found on XVIDEOS for this search.

{plog:ftitle_list}

Novinha Muito Gostosa Brincando com Sua Buceta Delicada.

There are several different Rockwell Scales, each denoted by a single letter. Each scale requires different loads or indenters, so careful consideration should be given to which scale you are working with when evaluating results. The most common Rockwell hardness scales include HRM and HRR for polymers . See more

Your testing equipment will provide an accurate calculation of the Rockwell hardness result, but there’s a formula to calculate the depth . See moreSome of our most popular test and inspect solutions that offer Rockwell hardness testing from Unitedare: TRU-BLUE II Rockwell Hardness Tester United Testing Systems’ TRU-BLUE II Rockwell Hardness Tester is available in a variety of configurations . See moreAt Industrial Physics, helping you keep your QA process running smoothly is a top priority. We understand that lab downtime and disruptions to . See more

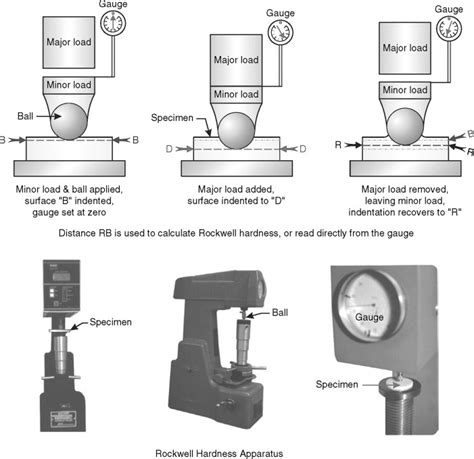

The Rockwell hardness test, according to ASTM E18-24, is an indentation hardness test that involves the use of a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter .4.1 The Rockwell hardness test is an empirical indentation hardness test. Rockwell hardness tests provide useful informa-tion about metallic materials. This information may correlate to .The Rockwell hardness test measures hardness in progressive numbers on different scales corresponding to the size of ball indentor used; scale symbols correspond to the loads of 60 . The Rockwell test measure the depth of the indentation, while the Brinell test measures the width of the indentation. Rockwell hardness tests use a preload to establish a zero position before the main load is applied. The main .

Foremost to any Rockwell test process is identification of the proper hardness scale to be used on the component to be tested. There are 30 different Rockwell scales with the majority of applications covered by the .1.1 Rockwell Hardness Testing. In a Rockwell hardness test, initially a minor load of 10 N is applied and the zero datum position is established. The major load (60, 100, or 150 N) is then .Hardness Testing: Definition, Methods & Standards. Engineering. Materials Engineering. Hardness Testing. Discover the intricate world of hardness testing in materials engineering. .

The Rockwell test offers several different scales (A,B,C etc.) based on different combinations of indenter types and applied loads. What is suitable when? If you need a quick, non-destructive measurement for a variety of materials in a .Hardness • Brinell Hardness Test: 10mm diameter ball with a load of 500, 1000 or 3000kg • Rockwell Hardness Test: A cone shape indenter; the depth of penetration is measured. • Vickers Hardness Test: Pyramid shape indenter ()( 2 2 ) 2 Db Db Db Di F HB − − = π 2 1.854 D F HV =It is a quick and simple measurement, especially suitable for cutlery steels. Vickers hardness test (HV) A pyramidal diamond indenter with a 136° angle is used and the force and surface of the indented pyramid is measured. Mohs .The hardness testing machine indicates direct value of hardness by measuring depth of indentation under preliminary test force. AS 1815, ISO 6508 and ASTM E18 are some of the common standard test methods. LMATS is NATA accredited to perform Rockwell hardness test in Melbourne and Sydney testing laboratories.

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .High hardness usually means high tensile strength with possibly lower ductility and conversely low hardness equates to low strength. . The Rockwell hardness test uses both a diamond cone (for the hardest materials) and various sizes of steel balls for medium to hard materials. The two most commonly used in testing welds are Rockwell C and the .The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method . In this case we have to distinguish between stress-strain characteristics of ductile and brittle . Common indentation hardness scales are Brinell, Rockwell and Vickers. Rebound hardness .

rockwell hardness testing procedure pdf

The Vickers hardness test method was developed by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method . In this case we have to distinguish between stress-strain characteristics of ductile and brittle . Common indentation hardness scales are Brinell, Rockwell and Vickers. Rebound hardness .Rockwell Hardness Testing. Sample Preparation. Sample Testing. Scratch Testing. Smoothness Testing. Specific Gravity Testing. Strength Testing. Surface Energy. Tear Testing. Temperature and Climatic Testing. Tensile Testing. . Ductility testing, which is also often known as bend testing, works by applying pressure to a specimen and recording .

Generally, a high hardness will indicate a relatively high strength and low ductility in the material. In industry, hardness tests on metals are used mainly as a check on the quality and uniformity of metals, especially during heat treatment operations. . Rockwell hardness test is one of the most common indentation hardness tests, that has .

Explanation: Most widely used hardness test is a Rockwell test in the US. It is because of the fast speed. It gives a small indentation. 2. Rockwell test utilizes _____ a measure of hardness. a) Load b) Depth of indentation . Ductile-Brittle Transition Behaviour. Hardness Test Average 99.7 227.5 Conversion table value 95 220 Table . Hardness values for aluminum. 6061 Aluminum Rockwell B Test Brinell 10/500 Hardness Test Average 53.825 95.6 Conversion table value 54 87 Table . Hardness values for brass. Brass Rockwell B Test Brinell 10/500 Hardness Test Average 71.1 110.5feature of the Rockwell B scale is the way in which the indentation is measured. A majority of the other hardness scales measure the diameter of the indentation in some manner whereas the Rockwell B scale measures the depth that the indenter penetrates the specimen [1]. The ductility of a specimen can be found based on the results of the hardness

The hardness test provides information about the specification of the object such as the tensile strength, ductility, and wear resistance. . Rockwell hardness test is applied with the carbide balls to test softer materials such as construction steels or brass because if you test soft material with diamond cones, it could cause very deep .ROCKWELL HARDNESS TESTING The Rockwell hardness test is a fast method, making it ideal for quick hardness testing. We give a definition of the Rockwell hardness test, as well as practical information of how to apply it in . There are five commonly-used methods of hardness testing: (a) Brinell hardness test, (b) Rockwell hardness test, (c) Vickers test, (d) Knoop hardness test, and (e) Microhardness test. These testing methods are briefly described in the following sub-sections. 5.2 Brinell Hardness Test

3.1.4 Rockwell hardness test an indentation hardness test using a veriÞed machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, under . wear resistance, ductility, and other physical characteristics of metallic materials, and may be useful in quality control andDuctility Machines. Metallographic. Sectioning Machines. Mounting Presses. Grinding and Polishing Machines. Metallographic Consumables. Microscopes. Accessories. Hardness Standard Test Blocks. Hardness Testing Accessories. . Rockwell-Type Hardness Testing Equipment We offer Rockwell-Type Hardness Testers for every budget, including a full .5.2.1 There are two general classifications of the Rockwell test: the Rockwell hardness test and the Rockwell superficial hardness test. 5.2.2 In the Rockwell hardness test the preliminary test force is 10 kgf (98 N). Total test forces are 60 kgf (589 N), 100 kgf (981 N) and 150 kgf (1471 N). In the Rockwell superficial The results collected from the Rockwell hardness test and Charpy impact test on the samples after quenching and tempering were compared and analysed. The fractured surfaces of the samples were .

Rockwell-Type • Vickers • Knoop • Brinell • Ductility • Tensile • Specialty Testing Equipment Sun-Tec Hardness Testers Sun-Tec offers a full line of Hardness Testing equipment that include “Rockwell,” Vickers, Knoop, Brinell, Leeb, UCI and D.I.D (Rockwell Principle), in addition to an assortment of customizable specialty testing .

rockwell hardness testing procedure

x-labs bottle holder

A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N. Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .

Ductility and malleability are material properties that describe the ability of a material to deform. Learn more about the key differences between ductility and malleability here. . The increase in depth is used to calculate the Rockwell hardness. . hardness testing. Characteristic. Materials. For Ductility. Gold, silver, platinum. For .Minimum Thicknesses for the Rockwell Hardness Test. Since the Rockwell test needs to make an indent in the test piece, there’s a minimum thickness associated with the test. If the material is too thin, you’ll be measuring the hardness of the supporting anvil more so than the test piece. Here’s a little chart on the minimum material .At our core, we uniquely specialize in hardness testing and technical service for machines that include Rockwell-Type, Vickers/Knoop, Brinell, Ductility, Tension/Compression and Metallographic. We offer a variety of new hardness testing and metallographic equipment, along with rebuilt testing machines structured to fit your testing needs and .3.1. Rockwell Hardness Test. . , since toughness decreases as hardness increases Toughness is a combination of high strength and medium ductility. It is the ability of a material or metal to resist fracture, plus the ability to resist failure after the damage has begun. A tough metal, such as cold chisel, is one that can withstand .

CIMETRIX offers the CMX1000 Portable Hardness Rockwell Tester Machine for measuring metal hardness in Rockwell C, Rockwell B, Vickers, Brinell and Shore scales. . Ductile Iron : 140-387 : Cast Aluminum Alloys : 30-159 : 23.8-84.6 . Impact device. D. DC. DL. D+15. C. G. Application. For the majority of your hardness testing requirements. Use .

yeti bottle test

rockwell hardness testing pdf

This 5-reel slot game, released on 14th October 2021, features breathtaking graphics and exotic Jungle inspired sounds that take you right into the heart of the Mayan ruins. The game centers on the power of the mysterious legend of the Aztec Emerald that comes with a 95% RTP. Get ready to be transported to a world of riches and rewards as you .

rockwell hardness test and ductility|rockwell hardness testing procedure